Cooling towers for food industry

Find out more on industrial food processing cooling system

Discover the applications of cooling towers in manufacturing and processing food into food industries

Boldrocchi TE designs and builds cooling towers systems for food industries worldwide. As concernes the food industry, the industrial food processing cooling system are used also for pasteurization and sterilization processes. In the food and beverage sector many types of industries are using cooling towers and heat exchangers

For example:

- oil refineries

- sugar industry

- distilleries

- chees industries (during the buttermilk cooling process)

- wine industries

- juice fruit industries

We are the leading cooling towers manufacturers in Italy: we can design custom cooling towers legionella free, build to satisfy customer needs, to make easier the industrial processes.

Our industrial food processing cooling system are requested and installed worldwide: we are able to satisfy any need, with highly customizable systems. Contact us to ask any information!

You could be interested in:

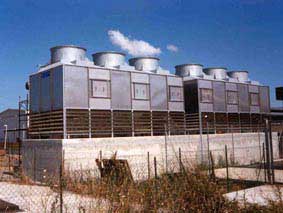

Case study: toamato industry

Cooling towers installed in Foggia in an agri-food industry. The cooling towers serve continuous sterilizers, cooling both glass and tin. We try to build the towers well and functionally, but as you can see, the customer completes the work excellently with the plant engineering part.

Efficient industrial food processing cooling systems

Boldrocchi T.E. provides industrial food processing cooling systems designed to meet the unique requirements of the food industry, focusing on hygiene and precise temperature control. Our systems help preserve product quality by maintaining stable processing environments, essential for food safety and compliance. Each cooling system is tailored to specific food processes, offering energy efficiency and reliable performance even in demanding conditions.

Advanced technology for food industry cooling systems

Our industrial food processing cooling systems incorporate advanced technology to optimize cooling efficiency while reducing operational costs. Designed for high durability, these systems minimize maintenance and improve production stability. By ensuring consistent cooling, our solutions help food processing facilities achieve high productivity, energy savings, and improved product quality.

Tailor made cooling towers for pasteurizers in food processing

Our cooling towers for pasteurizers are designed to meet the demanding temperature control needs of the food and beverage industry. By providing consistent cooling throughout the pasteurization process, our systems ensure that products are cooled effectively and efficiently after heat treatment. This precision cooling helps preserve product quality, extend shelf life, and maintain compliance with food safety regulations.