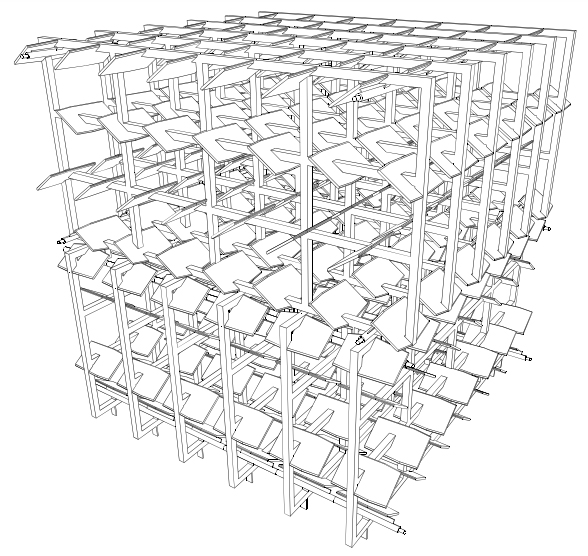

a) Reliable and long lasting.

b) Sturdy construction.

c) All parts in galvanised steel sheet painted with BTEPOWDERPAINT

before being assembled.

d) No welds on parts in galvanised steel sheet.

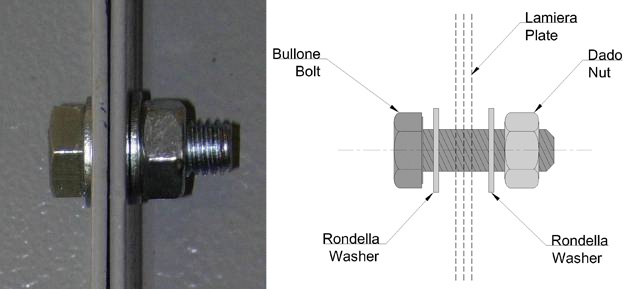

e) No self-tapping screws used to avoid damaging the paint.

Only bolts, nuts and double washers are used to protect the paint from scratches. Each bolt is tightened by special industrial tools of the highest quality that ensure correct tightening.

f) No transmission units. All motors are

directly coupled. Less maintenance,

consequently lower costs, lower

vibrations and lower energy

consumption.

g) All motors are connected in-plant to an external terminal board.

h) Electric motors with power of 15 KW

(8-pole) or over have external

lubricators.

i) No spray nozzeles used for the water distribution system, instead non-clogging gravity distributors, in AISI 304 stainless steel, connected with nuts and screws to the header.

j) Because the water gravity

distributor protects the exchange

surface, avoiding damage caused

by mechanical action of water on

the FILM type surfaces.

k) For a sturdy main header in steel tubing, hot dip galvanised after

working. The sturdy

construction protects the

distribution from possible

water hammer caused by

the pumps, protecting the

exchange surface.

l) Strong protective fan

exhaust grill.

m) Both fans and water

distribution network do not

require maintenance.

n) If necessary, they can be supplied with an extra exchange surface

section in order to increase the performance in a later time.

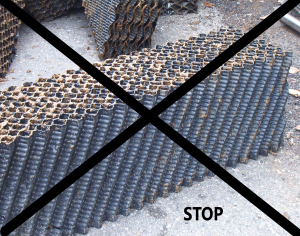

o) Because if fitted with LOLIPANN filling easy to clean and sanitise, they

can also cool dirt water and work in dusty environments. LOLIPANN

modules can be hot

sanitised in order

to prevent the

spread of

Legionella bacteria.

p) When equipped with a NON-clogging LOLIPAN surface, these tedious

and costly downtime

will never happen again.

To date, the Towers

supplied over 30 years

ago continue to work

with the initial

performance, without

any decay. Constant

performance and little

or no maintenance.

q) The towers can be supplied with an arrangement for cool water with

temperature up to 99 °C.

r) Because they can be supplied with special components suitable for

working in particularly rigid environments with temperatures down

to -50 ° C.

s) Because the electric motors can be supplied with certification for

American, Canadian and Russian standards.

t) Because the motor-fan part can be supplied in the ATEX anti-spark

version. To eliminate the spark problem it is not enough to use antispark engines, it is essential to provide an adequate anti-static

impeller.

u) Because the MEP series is designed to be easily loaded, transported

and unloaded on both trucks and containers.

v) Because all our cooling towers are electrically tested before shipment

to make sure that the motor-fan units reflect the absorptions required

by the strict Boldrocchi TE specifications. The technicians of our

parent company BODROCCHI SRL, the undisputed world leader in

ventilation too, have drawn up specifications that guarantee the

highest quality and reliability.

w) Because our highly qualified quality manager carefully inspects all the

equipment from the construction phase to the most meticulous

control of every smallest component, without neglecting the

management part of the bureaucracy.

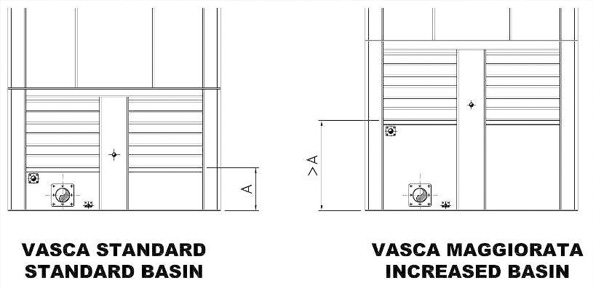

x) If it’s necessary, sump volume (if sump supplied) can be more than

doubled.

y) The water inlet connections and outlet connections (when supplied)

can be provided indifferently on four sides or where you want.

z) Because they can be customized.

aa) Because the new concept BOLDROCCHI TE Towers can be supplied in the "ECO" version with energy and

acoustic savings. If a normal tower

consumes 15 kW it is possible to have an

ECO version tower that consumes 3kW and

the acoustic impact goes from 80 dB (A) to

less than 70 dB (A). The higher initial

investment pays for itself in about 1 working year (8,000 h).

acoustic savings. If a normal tower

consumes 15 kW it is possible to have an

ECO version tower that consumes 3kW and

the acoustic impact goes from 80 dB (A) to

less than 70 dB (A). The higher initial

investment pays for itself in about 1 working year (8,000 h).

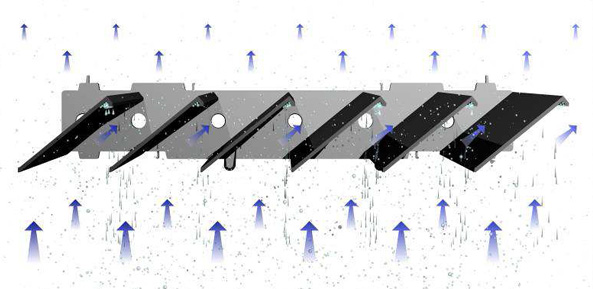

bb) Because they can be fitted with DRICONPLUS, patented and

tested by the

Politecnico di Milano,

the new inertial drift

eliminator, made of

several injection

molded polypropylene

panels assembled

following the air flow

direction thus

constituting an easy-to-handle single module The drift eliminator

section forces the air flow to suddenly change direction and fosters

the release of

suspended water

droplets.

the new inertial drift

eliminator, made of

several injection

molded polypropylene

panels assembled

following the air flow

direction thus

constituting an easy-to-handle single module The drift eliminator

section forces the air flow to suddenly change direction and fosters

the release of

suspended water

droplets.

The panels,

characterised by very

high mechanical

resistance, are at least

1.5 mm thick and can

endure temperatures as

high as 90 °C.

If needed, the performance of the section can be subsequently

increased in order to obtain nearly complete or complete retention of

the droplets in the air flow.

The higher the amount of the droplets removed, the lower the water

consumption and the risk of the spreading of Legionella bacteria.

The performance tests carried out at the Italian University Politecnico

di Milano in Milan, under test conditions which were similar to those

present in cooling towers, showed that the most performing

arrangement of DRICONPLUS drift eliminator was able to retain

100% of the droplets in the air flow.

DRICONPLUS panels are suitable for temperatures up to 90 °C and

can therefore be cleaned with high pressure water or steam jets.

If needed, the performance of the section can be subsequently

increased in order to obtain nearly complete or complete retention of

the droplets in the air flow.

The higher the amount of the droplets removed, the lower the water

consumption and the risk of the spreading of Legionella bacteria.

The performance tests carried out at the Italian University Politecnico

di Milano in Milan, under test conditions which were similar to those

present in cooling towers, showed that the most performing

arrangement of DRICONPLUS drift eliminator was able to retain

100% of the droplets in the air flow.

DRICONPLUS panels are suitable for temperatures up to 90 °C and

can therefore be cleaned with high pressure water or steam jets.

The LOLIPANN polypropylene panel is injected-molded and thus characterized by precise

workmanship, sturdiness and is relatively thick (in terms of millimeters and not centimeters). Other

features are listed in the technical card “ technical features 001” enclosed.

The different elements are pressure connected by means of four taper pins positioned

approximately on the four corners. The number of panels that can be connected in a single row is

almost infinite.

The connecting geometry is intentionally fixed to avoid mistakes during assembly that would

inevitably lead to yield variation.

The total number of sections made up of LOLIPANN panel is uniformly distributed so that the free

sections are also uniform. There are no spaces that contain an excessive number of sections nor

ones that are excessively free.

Sections made up of LOLIPANN panels can be overlapped at alternate axes until the

required thickness has been reached. For thickness up to 1500/1800 mm, sections can simply be

overlapped; for greater thickness, in-between supports must be placed.

The surface obtained with the LOLIPANN panels is splash type, thus able to perform even if loaded

with dirt, lime or organic material. This feature enables the surface weight, which when clean

weighs as much as the Film surface, to increase significantly when used.

For this reason the support chooses preferably uses a system that supports "from below" and not

"from above". In other words, the sections are NOT suspended, by REST on the special supports.

Each LOLIAPNN panel and each section obtained by connecting the panels to each other is

complete with special lower clamps needed to guarantee section stability (they hook unto the

supports, between the panels of the lower section, etc).

The versatile LOLIPANN panels can substitute almost all sections used today. Easy to use, they can

be connected to each other easily and intuitively (even though instructions are always provided)

making their assembly possible directly on the premises by relatively unskilled personnel.

Brief description of the main features of the LOLIPANN panels

◦ Panel material:

polypropylene with mineral filler

◦ Moulding process:

injection

◦ Minimum thickness:

2mm

◦ Temperature at start softening point:

about 98°C

◦ Connecting panels:

with pressure pins that are parallel to the surface

◦ Type of resulting sections:

fixed geometry

◦ Dimensions of each section:

height 300 mm, width 600 mm. length 100 mm X No. panels

◦ Number of panels per linear metre:

10

◦ Number of panels per m³:

56

◦ Type of support required:

resting

◦ Main panel axis:

parallel to liquid/air flows; perpendicular to the surface

◦ Degree of interchangeability:

excellent with counter-current flow towers