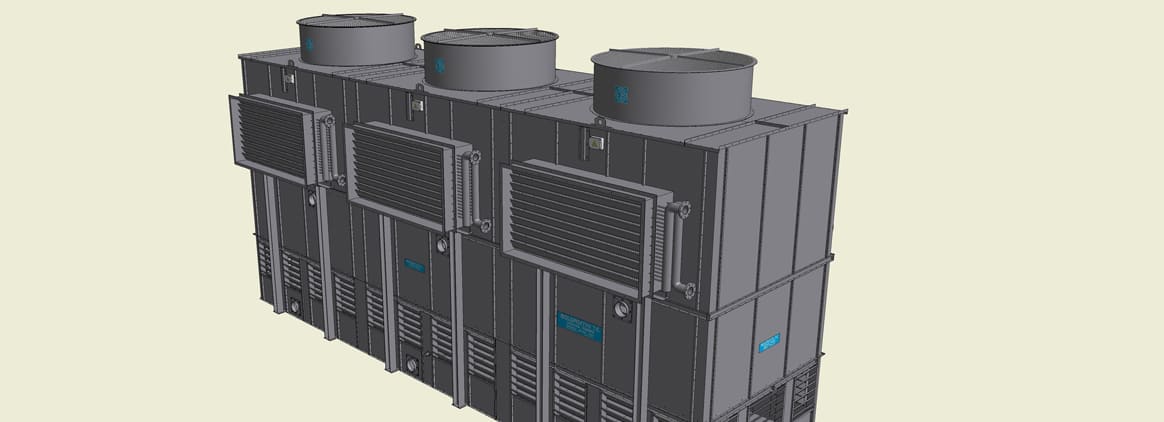

Cooling tower plume abatement / plume control

What is a cooling tower plume and how to control it

WINTER PLUME CONTROL IN COOLING TOWERS / WET & DRY

The theory of operation behind equipment for water evaporative cooling is well known: the fluid to be cooled (water) is forced into close contact with a substantial air flow. Part of the water evaporates, is absorbed and carried away by the air. On leaving the tower, the air is notably warmer, it contains more water and presents a higher dew point. Particularly during winter months, when the outside temperature falls, as soon as the stream of air - which is warm and saturated with moisture - comes into contact with the atmosphere outside, it is suddenly cooled. When the temperature of the airflow falls below the dew point, part of the water contained in it condenses, giving rise to the characteristic visual phenomenon which is vapour plume. Heavier droplets fall, causing a slight rain effect.

HOW TO CONTROL PLUME?

The brief introduction above is necessary to show the principles behind the control system we offer.

First of all, a post-heating system for the escaping vapour has been considered. This is made of a water/air heat exchanger located at the vapour outlet. In this case, the heating fluid is the actual water to be cooled, used before cooling, of course.

The exchanger located at the outlet creates constant flow resistance on the air side, and therefore requires greater energy consumption from the fans (even in summer, when it should not be needed), and hence a rather small total surface area would be necessary (2 to 4 rows).

There are various problems involved, which we shall attempt to outline below.

a) Also in winter with air at 0°C, the temperature of the vapour is in a range between the inlet and outlet water temperature (see the evolution of the saturation curves on the psychometric chart). As a consequence, the heat contribution transferred to the vapour is little, with the consequential rise in temperature and deviation from the saturation line being equally slight. The only real effect is the physical opposition as the vapour leaves, thus reducing the density of the vapour and encouraging its absorption into the atmosphere.

b) How to handle the exchanger issue? If water is allowed to remain in the exchanger even when pumps are not functioning, the risk of bursting owing to the cold is present (the freezing time of the water in the exchanger pipes is considerably lower than that of the water in the rest of the system, including the main pipes). Conversely, if the exchanger is to be drained every time the system is stopped, oxygen will inevitably enter the system, and therefore the risk of corrosion must be considered; a stainless steel exchanger would be perfect, but somewhat expensive.

We have made a different choice. Based on the assumption that less air is required to remove the heat during the colder months, we have engineered the following system:

- penalising the fans in winter, which would have to work at full speed the whole time, the dew point temperature of the vapour is lowered with the controlled introduction of a certain amount of air from outside.

- By lowering the dewpoint temperature, the difference in temperature between the external air and the vapour is reduced by approx. 50 and the actual cooling time of the vapour is increased.

Much of the condensation caused by the sudden cooling of the vapour occurs inside the plenum chamber, which is part of the tower.

The lower the external temperature, the greater the external air demand, i.e. in those conditions where the air required by the tower is low. The introduction of external air is controlled by servo-controlled gates.

Practically speaking, this system can be applied to evaporative cooling equipment to great advantage, where a forced draught system is in operation and suction fans used.

Where possible, the plenum chamber should be installed between the water distribution system and drift eliminators, or between the drift eliminators and the fan if it features servo-controlled dampers. During summer months, the dampers remain closed and disabled by the system.

During winter months, a proportional thermostat to check water temperature will control the opening of the dampers. When fully open, it will also be responsible for the proportional stopping of the fans, where necessary.

Of course, the system may be fitted with water/air exchangers on the dampers.

In this case, the difference in temperature between the water to be cooled and the external air is higher, with the following advantages:

- a) the temperature of the vapour is raised, whilst the dew point temperature remains the same (deviation from the saturation curve);

- b) heat is removed with a dry system, therefore no evaporation is required for removal.

- c) Unfortunately, the above-mentioned problems of frozen pipes and corrosion remain.

WINTER PLUME PHENOMENON IN COOLING TOWERS

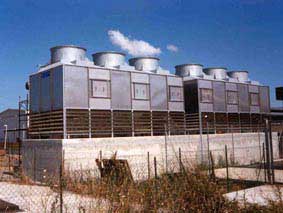

As shared by the operators of this sector, equipment designed for the thermal recovery of service cooling water - known as cooling towers or evaporative towers - enables substantial volumes of water to be cooled at relatively little cost by evaporating a small percentage (usually around 2/3 of the actual water).Evaporation is encouraged by a considerable volume of air, circulated by fans usually located at the top of the towers. The air comes into close contact with the water to be cooled.

The air flow leaving the fans is usually warmer and much more humid than the surrounding atmosphere.

Harmless plumes of saturated air escaping from cooling towers installed to serve industrial plants have become, in some cases, a traditional characteristic of the landscape.

As mentioned, the phenomenon is totally harmless. However, while in summer the resulting effects are decidedly irrelevant, during the colder season they may be grounds for contention with neighbours who find their premises assailed by damp, and their yards made slippery and icy. Similarly, contention may arise with authorities in charge of traffic should the phenomenon affect roadways. More recently, authorities concerned with environmental protection have also raised objection as increasing attention is focused on the impact the manifestation has on the territory, which is not always seen in a good light.

The question Boldrocchi T.E.'s technical department asked itself is whether this annoying phenomenon of winter plume in cooling towers can be eliminated or at least reduced without excessive cost.

The answer we can offer today is mostly positive.

With our plume abatement innovative system, the phenomenon can be reduced drastically and proves relatively inexpensive in terms of both initial investment and running costs.

The unique device that enables partial control of winter plume is based on recognised principles. It does not involve obstructing the fan outlet (which would penalise the tower during summer months) and does not call for any energy other than that required for regular operation.

Unfortunately, this system is not usually applicable to existing towers, whilst it can already be implemented on request on all towers produced by Boldrocchi T.E.