FAQ

General Questions about Cooling Towers

-

1. What is an industrial cooling tower and how does it work?

An industrial cooling tower is a system that uses evaporation to lower the temperature of process water. This system is essential for dissipating heat generated in various industrial sectors.

-

2. What are the advantages of cooling towers compared to other cooling solutions?

Cooling towers are the most cost-effective method to remove heat from an industrial process. More economical in both purchase and running costs.

-

3. How do I choose the right cooling tower for my company?

The choice depends on factors such as the volume of water to be cooled, the desired cold-water temperature, and the work environment. Boldrocchi TE provides free technical consultations to help identify the ideal solution.

-

4. What is the difference between open-circuit and closed-circuit cooling towers?

Open-circuit cooling towers, the most cost-effective solution, cool down water by directly exposing it to air. Closed-circuit cooling towers cool down water separating it from the primary circuit using a delicate and costly shell and tube heat exchanger, which, if it is not well managed, can cause sudden shutdowns.

Products and Technical Specifications

-

5. What types of industrial cooling towers does Boldrocchi TE offer?

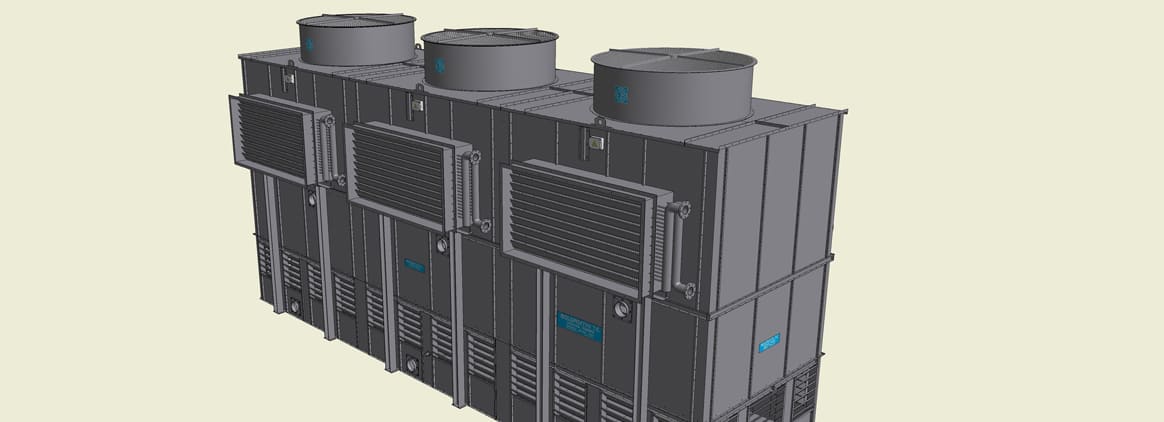

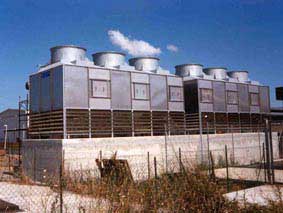

We offer two main series of evaporative cooling towers:

- MEP Serie: Pre-assembled cooling towers designed for continuous and heavy-duty use, ideal for intensive industrial sectors. These towers arrive nearly fully assembled, reducing installation time and costs.

- CMK Serie: Suitable for large water volumes, similar to the MEP series but assembled on-site.

- 6. Boldrocchi TE Cooling towers can be equipped with the LOLIPAN NON-clogging, cleanable and sanitizable surface, ensuring minimal maintenance even in industrial environments with contaminated water and air.

-

7. Boldrocchi TE Cooling towers equipped with the LOLIPAN NON-clogging exchange surface can be sanitised to prevent the Legionella bacteria.

Boldrocchi TE cooling towers are equipped with high-efficiency droplet separators, Driconplus, unique and patented worldwide, which capture up to 100% of the expelled droplets. They are essential for eliminating the entrainment of droplets, which in conventional cooling towers can cause issues with the Legionella bacteria.

-

8. Are Boldrocchi TE cooling towers eco-friendly?

Yes, our models are designed to optimize water and energy consumption, reducing environmental impact. The MEP Series also includes ECO (Ecological) versions that achieve energy savings of over 75% compared to traditional towers.

-

9. How long does a Boldrocchi TE cooling tower last?

Our towers are built with high-quality materials and designed to last decades with minimal regular maintenance. Some of our models have been in operation for over 50 years under continuous heavy-duty conditions.

Maintenance and Support

-

10. How often should a cooling tower be maintained?

Maintenance frequency depends on usage and environmental conditions, but periodic inspections every 6-12 months are recommended.

-

11. What should I do if the cooling tower shows signs of inefficiency?

Although rare, if doubts arise, please contact our support service. We offer free technical assistance for diagnostics and repairs, ensuring a quick return to full efficiency.

Purchasing and Installation

-

12. How much does a Boldrocchi TE cooling tower cost?

The price varies based on the model, size and customizations required. Contact us for a free, no-obligation quote.

-

13. Can cooling towers be installed outdoors?

Absolutely, it is mandatory. Our models are designed to withstand extreme environmental conditions (from severe cold to desert heat).

Industries and Applications

-

14. Which industries use Boldrocchi TE cooling towers?

Our cooling towers are used in sectors such as oil mills, sugar factories, distilleries, dairy industries, wineries, breweries, juice production, pasteurizer cooling, concentrators, evaporators, autoclaves, general food processing, refineries, power plants, pharmaceutical facilities, cement factories, paper mills, glass factories, heat treatment plants, steelworks, rolling mills, waste disposal, soap manufacturing, polystyrene molding, rubber molding, paint industries, compressor cooling, refrigeration cooling, oil press cooling, and reactor cooling.

-

15. Can a cooling tower be used for small plants?

Certainly. We offer solutions ranging from a few cubic meters per hour to thousands cubic meters per hour, suitable for both small and large industrial applications.

Contacts and Certifications

-

16. Is Boldrocchi TE certified for quality?

Yes, we are ISO 9001 certified, ensuring high standards in production processes and product quality.

Yes, Boldrocchi TE is a member of the renowned CTI Cooling Technology Institute.

-

17. How can I request a quote or more information?

You can contact us by phone, email, or by filling out the contact form on our website.

-

18. Where is Boldrocchi TE located?

We are base in Biassono, Monza Brianza, Italy, at Via degli Artigiani, 5. We operate globally, serving clients and partners worldwide.

-

19. Which cooling tower is the most reliable?

Boldrocchi TE cooling towers are the most reliable and require less maintenance due to their robustness, the quality of their components, and their high reliability. Their expected lifetime is more than 50 years.

-

20. Which cooling tower requires the least maintenance?

Boldrocchi cooling towers are built with high-quality components that require little to no maintenance. They are designed for continuous operation.

-

21. Which is the most economical cooling tower?

Boldrocchi TE cooling towers, due to their high reliability, sometimes cost more than traditional towers. However, because of their high reliability and lower maintenance requirements, they have the lowest operating costs in their category.

-

22. Which cooling tower is the most energy-efficient?

The ECO series cooling towers from Boldrocchi TE have an energy consumption reduction of -50% to -75% in installed electrical power, making them the most energy-efficient option already from the first year of use.

-

23. Which cooling tower can work with high water temperatures?

Boldrocchi cooling towers can operate with hot water up to 99°C. They are specifically built with components suitable for high temperatures.

-

24. Which cooling tower is NON-clogging?

Boldrocchi TE evaporative cooling towers are defined as NON-clogging thanks to their NON-clogging Lolipan heat exchange pack and NON-clogging AISI 304 stainless steel water distributors.

-

25. Legionella in cooling towers?

Boldrocchi evaporative cooling towers are highly resistant to Legionella contamination. Thanks to its NON-clogging and sanitizable Lolipan heat exchange pack and the NON-clogging water distribution system, chemical disinfectants can reach all components, allowing perfect sanification.

Legionella in cooling towers is often mentioned. A cooling tower can be an ideal environment for Legionella bacteria to proliferate if stagnant water is present at the right temperature. There is no sterile material where the bacterium cannot proliferate if there is stagnant water at a certain temperature. Boldrocchi cooling towers are designed to have no water stagnation. The NON-clogging water distribution system, with stainless steel nozzles, ensures continuous flow. The Splash Lolipan heat exchanger is NON-clogging, and the high-efficiency Driconplus drift eliminators capture all water droplets. Thanks to all these components, Boldrocchi cooling towers do not retain dirt that could lead to water stagnation. The chemical disinfectant reaches all areas, keeping the entire structure clean and sanitized. For this reason, Boldrocchi provide evaporative cooling towers defined as LEGIONELLA-free.

-

26. Can a cooling tower burn?

All plastic materials are flammable and therefore dangerous. The structure of Boldrocchi cooling towers is not made of plastic and/or fiberglass, which are easily flammable. Boldrocchi evaporative cooling towers are built with a sturdy metal structure, SENDZIMIR galvanized, plus a strong oven-cured polyester powder coating, making them resistant to flames.

-

27. Axial vs. centrifugal cooling towers?

Boldrocchi manufactures only axial cooling towers, which consume about 50% less electricity and require no maintenance.