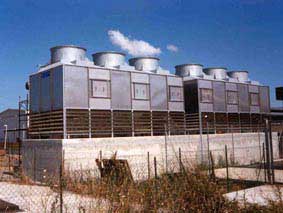

Cooling towers in steel plant: how they work?

Why cooling towers are used in iron and steel plant?

The use of cooling towers is therefore fundamental in many situations & industries such as the iron and steel industry, the metallurgical sector, refineries, glassworks, the municipal solid waste disposal sector, the chemical industries, the plastics industry, purifiers, etc. Today we are going to analyze the use in the first two sectors: the steel and metallurgical sectors and we find out more about how cooling towers work in steel plant.

First, how does a cooling tower work?

In these two sectors the evaporative towers are mainly installed in which the tower is crossed, due to gravity, by the water that must be cooled in a way such as to yield its own caloric content by direct exchange with air.

The heat is transferred partly by convention (between hot and cold air) and partly by exploiting the latent heat of evaporation of the water passing in the form of water vapor in the air.

The difference in pressure between the water vapor and the air vapor in the environment causes the evaporation that occurs when the temperature of the water and the boundary layer reaches the temperature of the wet air bulb.

The role of cooling towers in steel plants

Cooling towers play a crucial role in ensuring operational continuity and energy efficiency in steel plants. In an industry where production processes generate high levels of heat, cooling is essential to maintain equipment at the right temperature, preventing overheating and operational disruptions. By using state-of-the-art cooling towers, steel plants can significantly improve their performance, reduce energy consumption, and lower operating costs.

Benefits of cooling towers for the steel industry

The adoption of efficient cooling towers offers numerous benefits for steel plants, including:

You could be interested in: