What are cooling towers? Industrial applications of cooling towers, definition and how they work

When within an industrial process there are thermal cycles (necessary to carry out the process e.g. Temperature or generated by the process e.g. Heating oil presses), it is necessary to remove the unused heat or produced in excess in order to continue the process.

Not eliminated heat would accumulate where produced and make impossible to continue production.

Maybe there are not many cases in which the temperature is really important, important is to stabilize thermally the use in order to allow continuing production.

The fluids most used to cool industrial processes, because they are the most economical and the most available, are, by far, the air and water.

They are used both in a direct way; directly cooling the user and in an indirect way: cooling other fluids (e.g. oil) which then cool the user.

Industrial cooling towers applications

We are cooling towers manufacturers and we serve different markets: our towers are in demand in a wide range of industries, from food to the chemical industry.

Sectors that provide a thermal cycle in their production process:

- Refineries

- Sugar (sugar industry)

- Distilleries

- Production of energy (gas turbines, reciprocating engines, etc.. Users)

- Chemical Industries

- Pharmaceutical industries

- Food

- Industries canning and juice

- Glassworks

- Ironworks

- Plastics industry

- Rolling mills and wire mills

- Iron foundries

- Non-ferrous metals (manufacture)

- Heat Treatments

- Paper Mills

- Manufacture of wood (veneered panels etc.. Made with resins)

- Disposal Waste (MSW Municipal Solid Waste)

- Purifiers (of liquids)

- Plumbing and heating equipment Wholesalers

Industrial cooling towers: how they work

The water can be cooled basically in three ways:

- Dry (radiators, dry cooler)

- By means of chiller

- Wet, by evaporative cycle

A dry heat transfer takes place if there is a difference in temperature between the two fluids, one internal to the tubes (usually water but not only) and the other outside the tubes, usually finned to increase the exchange surface. The external fluid is usually air.

The transfer of heat from the hotter fluid to the colder one occurs as long as there is a difference between the two temperatures and as permitted by the medium (size and efficiency of the heat exchanger).

The heat must be transferred to the air and therefore also this one must be in sufficient quantity to receive it.

A flow of air moved by fans, invests a battery of finned tubes, or bundles, where the fluid to be cooled (water but not only) circulates inside the tubes.

The temperature difference between the air inlet and outlet, and the flow rate of the air itself, determine the amount of heat removed.

Cooling by means of refrigeration cycle

It's what allows you to reach the temperature you want even well below zero, it is not affected by the temperature outside, unfortunately it is quite expensive, both as initial investment, as both as initial investment and operating cost and is normally used only when cannot be done otherwise.

Wet cooling or evaporative

It’s, absolutely the most flexible and economical system to cool down industrial water; in effect, is, by far, the most used system in industries that have to cool down large quantities of water.

The water cooling is obtained facilitating the evaporation of a small quantity of the same water.

The reference value that restrict the process, it’s the one related to the wet bulb of the air; in Italy the average maximum value during the summer time vary from 24°C in the north, to 25,5°C in the south.

With these values, the water could be cooled till 27/28°C.

Also in water cooling towers, in need, the temperature of cooled water, can decrease at the drop of the external values of the air.

That is, it’s possible to realize an eco-save, reducing the air capacity.

The machineries that perform this type of cooling are known as “evaporation towers” or “cooling towers”.

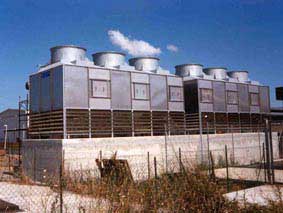

Essentially they are made up from a case of containment of components, from a distribution water system, from a “filling”, from a collecting tank of the cooled water and from a fan that produce an air flow through the “filling” .

In the filling, where the water to be cooled and the air joint in a intimate contact, a small quantity of water (about 4 – 5 % of the flow) evaporate detracting heat from the remaining body of water.