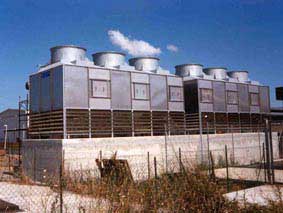

Treating cooling tower water

Discover more about the treating cooling tower water basics

The periodic control of the cooling towers is essential to verify if all the equipment that compose them are still in good condition after a few years of use, generally the situation that you notice is that of intact towers, still able to do their job, but they present problems at the level of smaller components, such as condensers, which unfortunately are caked with carbon, sediments settling on the bottom can affect the quality of water, favoring the multiplication of bacteria and harmful organisms.

Just as the name implies, the cooling towers work by exploiting the latent evaporation power of the water, which thanks to this process is evaporated and filtered by all the harmful organisms, and then to the condensers and cooling towers where it will be ready for use. This system alone, however, can not guarantee the total absence of algae and mucilage inside the water that is why even if it imposes a greater expense, it is necessary to insert in the cooling towers two metering pumps, to disperse the limestone first, and then the algae, these systems that are now standardized and sold at fairly economical prices, also provide a control unit that provides automatic purge and monitoring of water quality. Thanks to these systems we guarantee an economic saving, a much more valid system than the one used in the past, and an energy saving due to the reduced demand for maintenance of the latest generation systems.

Tips for treating water in cooling towers:

Although the towers are built with state-of-the-art technological tools, it is advisable to contact a specialist to check the quality of the water over time, this proceeds by carrying out analyzes that exclude the formation of harmful organisms and minimize the risk that these may form. The biological treatment of the water, allows to ensure the good functioning of the plant, which face needs maintenance in their oldest technological components.

Generally the water that circulates in these plants must maintain typical values, indicated in appropriate tables to be perfectly purified and free of algae and carbonates, therefore safe for health. Only through thorough analysis will it be possible to verify its integrity. Among the main values ??that must be taken into account are the hardness of the water; which must be above 35 degrees F, otherwise it must be softened to avoid deterioration of the cooling tower components and paying close attention to purging and air conditioning cycles.

Also very important is the concentration of chlorides which must not exceed 6-700 ppm, which indicate the presence of brackish water, which must be immediately treated by a specialist, to avoid corrosion processes of the main components of the cooling towers. Very important the heat of the pH, a measurement of more than 9-9.2 certainly indicates the presence of polluted water that requires immediate treatment.

Through the appropriate chemical treatments by a specialist it will be possible to take advantage of the good functioning of the cooling towers that ensure water of excellent quality, and good performance of the plant without carbonates and algae, which are the two organisms that most endanger the good operation of the entire installation.

Find out the applications of cooling tower in food industry , how they work in steel plant